DISCOVER GREENEDGE BIOJAC™

Car Wash Water Reclamation System

Transform your car wash with the efficiency of BioJac™ Water Reclamation Systems. As the world seeks sustainable solutions, Bio Work Best.

70% - 80% Car Wash Water Reclamation

Turn the tide in your favor with GreenEdge's BioJac™ Water Reclamation System for in-bay automatic and tunnel systems.

Say goodbye to the hassles of stringent water regulations, rising costs, and unpleasant odors.

Not only had the BioJac system relieved the car wash of its previous horrible odor problem, but that the ability to use BioJac Water in every application except the final rinse arch, allowed the Zero-Discharge Car Wash to obtain an average base cost of $5/vehicle.

Transform your car wash with the efficiency of BioJac™ Water Reclamation Systems. As the world seeks sustainable solutions, Bio Work Best.

Experience the BioJac™ Difference:

70% - 80% Water Reclamation

Reliable, Steady Stream of Pre-Wash Water

Fast, Easy, One-Day Installation

Absolutely No Foul Odor - Unlike Other Technologies

Minimal Maintenance - Just Add Microbial Booster

Completely Scalable - Grows With You

Whether you're running an in-bay automatic or a tunnel wash system, wastewater challenges shouldn't compromise your profitability. In an era of rising water costs and tightening regulations, water reclamation isn’t a luxury—it’s a necessity.

Customized for both in-bay automatic and tunnel wash systems, BioJac™ emerges as the trailblazer driving your car wash toward unmatched efficiency and profitability.

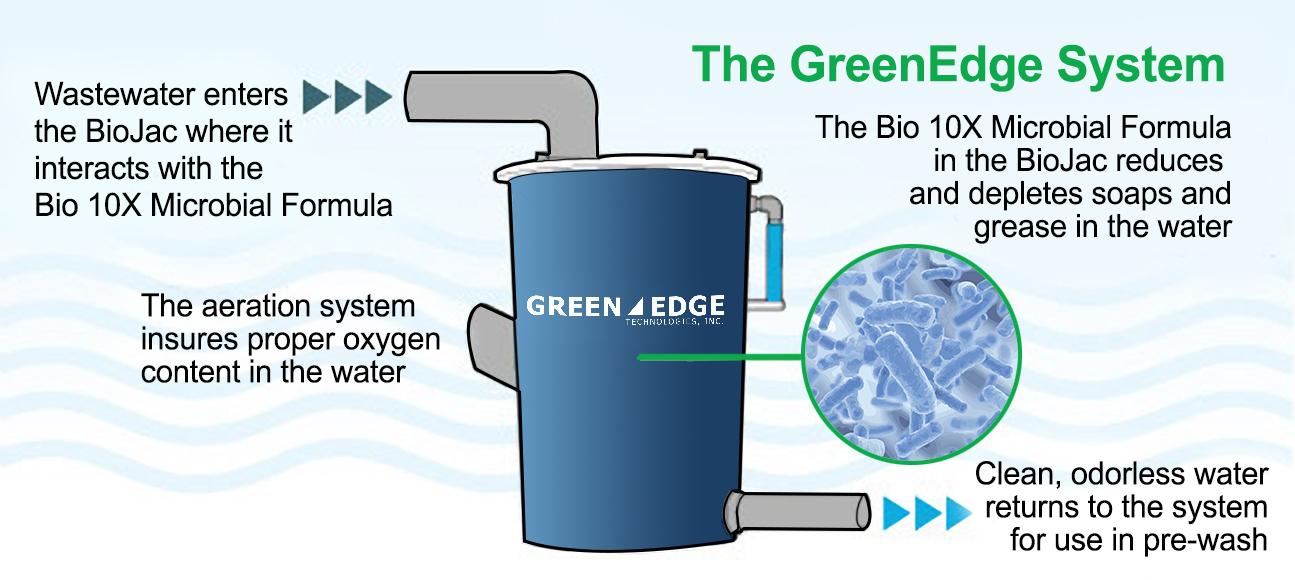

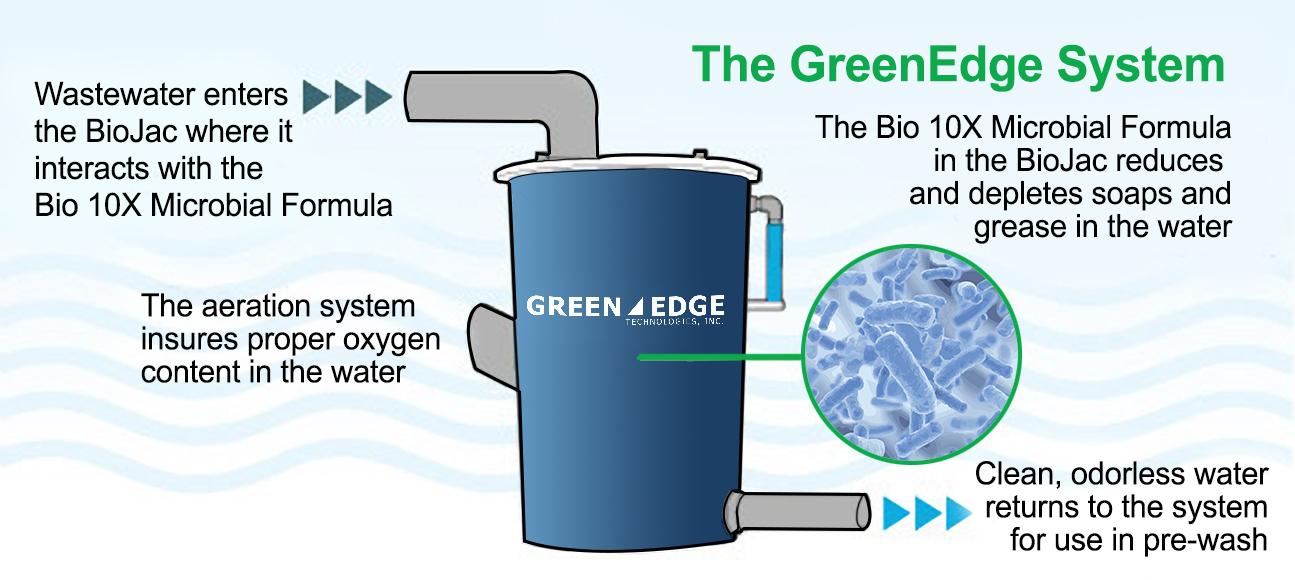

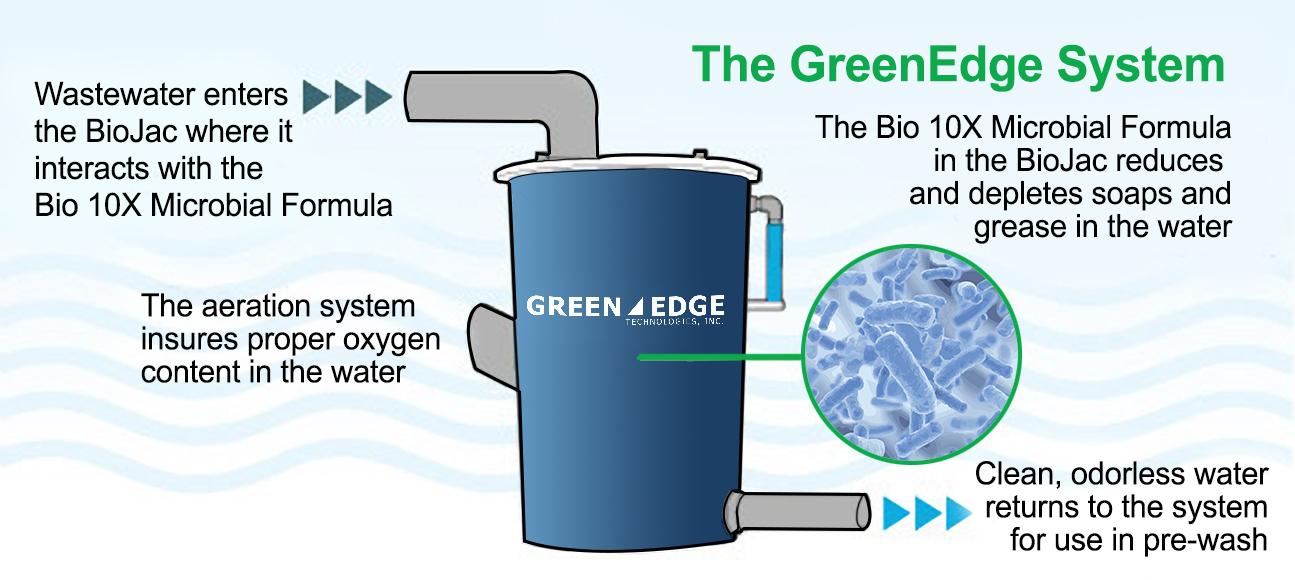

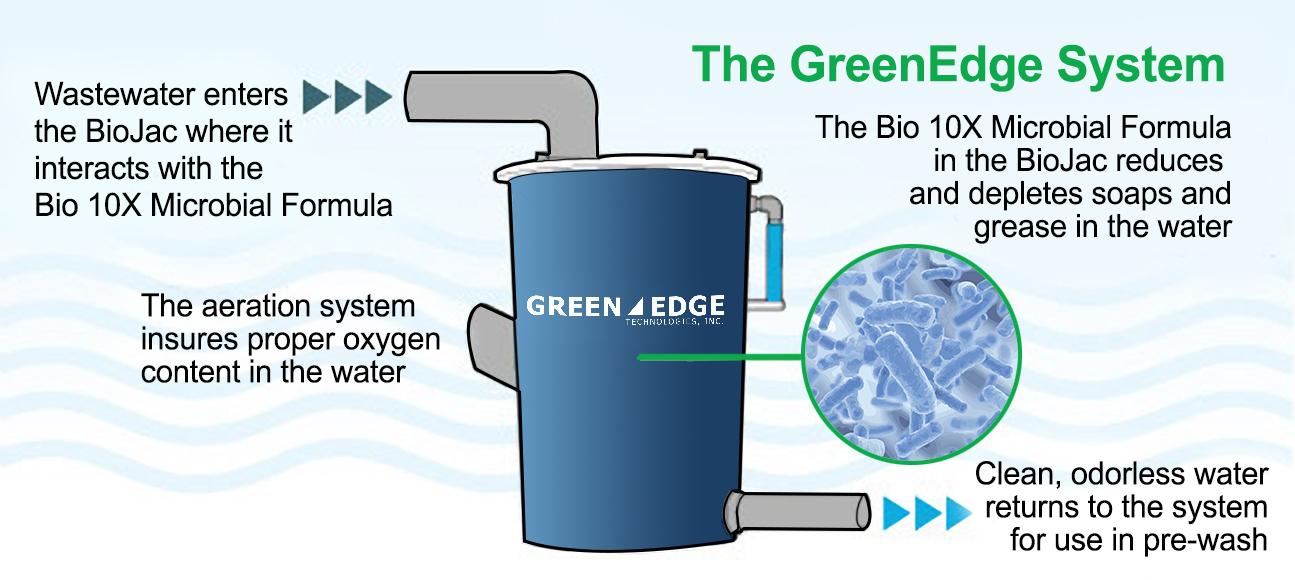

Our approach utilizes cutting-edge bioremediation, converting wastewater into reusable water, marking a significant reduction in environmental impact. Briteway Car Wash serves as a testament, saving 80-90% on water expenses after integrating BioJac™, and enjoying a subsequent surge in patronage.

Ready for unparalleled operational efficiency? Contact us today for a FREE consultation on transforming your car wash with BioJac™.

Slash your water bills with BioJac™.

Our water reclamation system reduces overheads by reusing water within your operations. Enhance your profit margins by sidestepping non-compliance fines. Choose BioJac™, choose smart savings.

Transform water usage with BioJac™.

Our system innovatively recycles wastewater, allowing repeated usage and drastically reducing your fresh water requirements. By reclaiming and reusing, you not only cut costs but also conserve a vital resource.

Experience freshness with BioJac™.

Our innovative technology treats wastewater, eliminating the root cause of foul odors. As a result, your workspace stays fresh, hygienic, and pleasant, adding to your customer's positive experience.

BR165.1 ccw.pkg

BioJac System

Commercial Car Wash Package

Looking for all the specs & details?

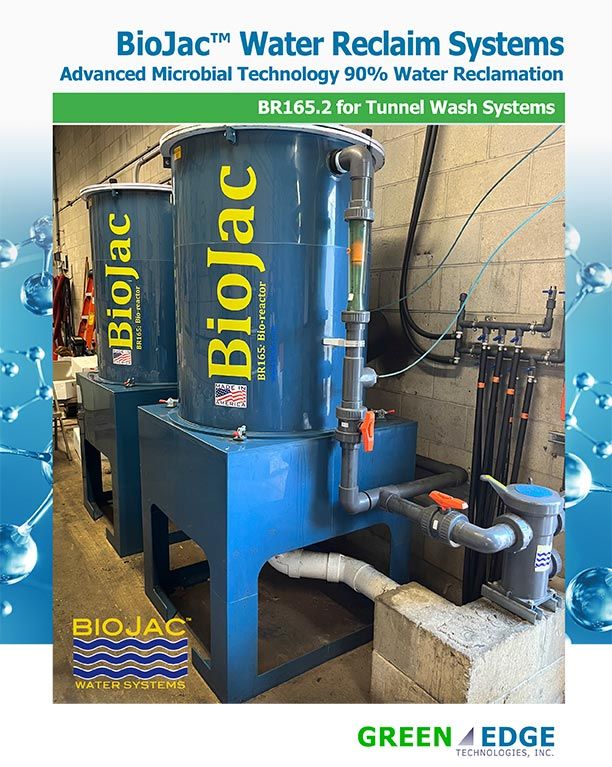

BR165.2 ccw.pkg

Dual BioJac System

Commercial Car Wash Package

Looking for all the specs & details?